Automated Vacuum Mooring for Non-Standard Terminal Applications

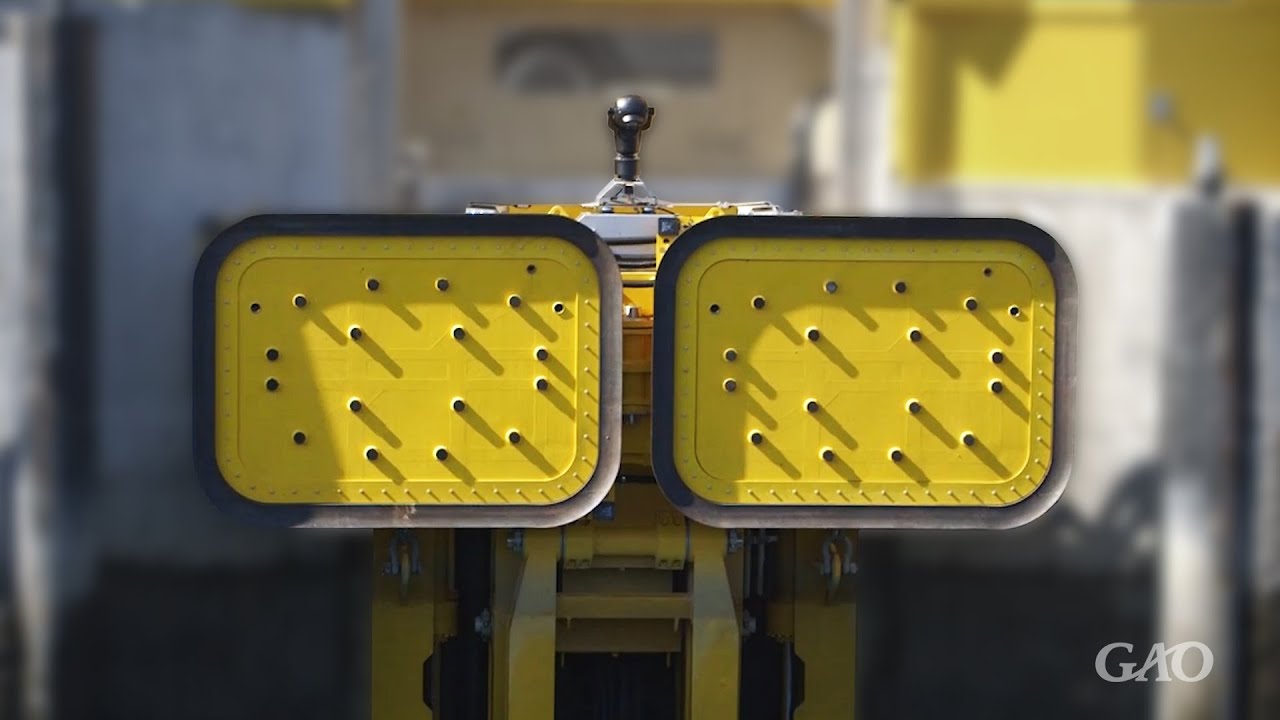

MoorMaster™ hands-free mooring is transforming operations across a wide range of terminal environments by replacing conventional mooring lines with fully automated vacuum technology. The system eliminates dangerous rope-handling activities, enhances safety, and enables faster and more predictable berthing operations, helping terminals improve efficiency and vessel turnaround times.

MoorMaster™ units are installed directly on the berth to securely hold vessels in position throughout their stay. By maintaining a consistent and controlled distance between the vessel and the quay, MoorMaster™ ensures safe operations even in challenging conditions, reduces vessel movement, and supports a more reliable interface with terminal infrastructure.

Benefits

- Removes hazardous mooring lines-handling, (lines present fall risks at low water)

- Allows mooring to be performed remotely, potentially many kilometres from the lock

- Effective controls of vessel surge throughout the lockage process; lines lack control at low water due to the extreme angles from quayside to vessels

- Eliminates dangerous oscillating roll motion caused by lines with water turbulence

- Speeds up mooring and allows faster filling or drainage of locks

Proven Performance in Ports

Discover how ports around the world are using MoorMaster to speed up operations, improve safety, and reduce emissions.

"Hands-free mooring provides time, safety and monetary benefits to carriers by reducing the overall cost of vessel transit"

Winner reveal at Heavy Lift Awards 2020

"According to the staff, the system has resulted in faster transit through the locks and contributed to greater safety for the workers around the lock. This is just one example of how the federal government is using the internet of things."

U.S. Government Accountability Office, report GAO-20-577

References

St Lawrence Seaway, US and Canada

Moorings: Four to five per day in each lock

Vessels up to LOA 225m

Challenge

- 15 locks in the US and Canada, each completing four to five moorings per day

- Vertical travel in locks between 12 and 15m

- Locks in remote locations forcing operators to drive up to four hours

Solution

- MoorMaster™, units mounted on vertical rails inside the lock chamber wall securing the ship during the lockage process

- Locks completely remotely operated with no humans by lock

Key benefits

- Transit times reduced by nearly seven minutes per lockage thanks to fast mooring and less vessel motion during drainage

- Resources freed up through automation, reduced travel time, and economies of scale

- Increased the pool of vessels worldwide that are able to enter the locks

- Eliminated safety hazards caused by handling mooring lines